Understanding Kiln Drying

What is Kiln Drying?

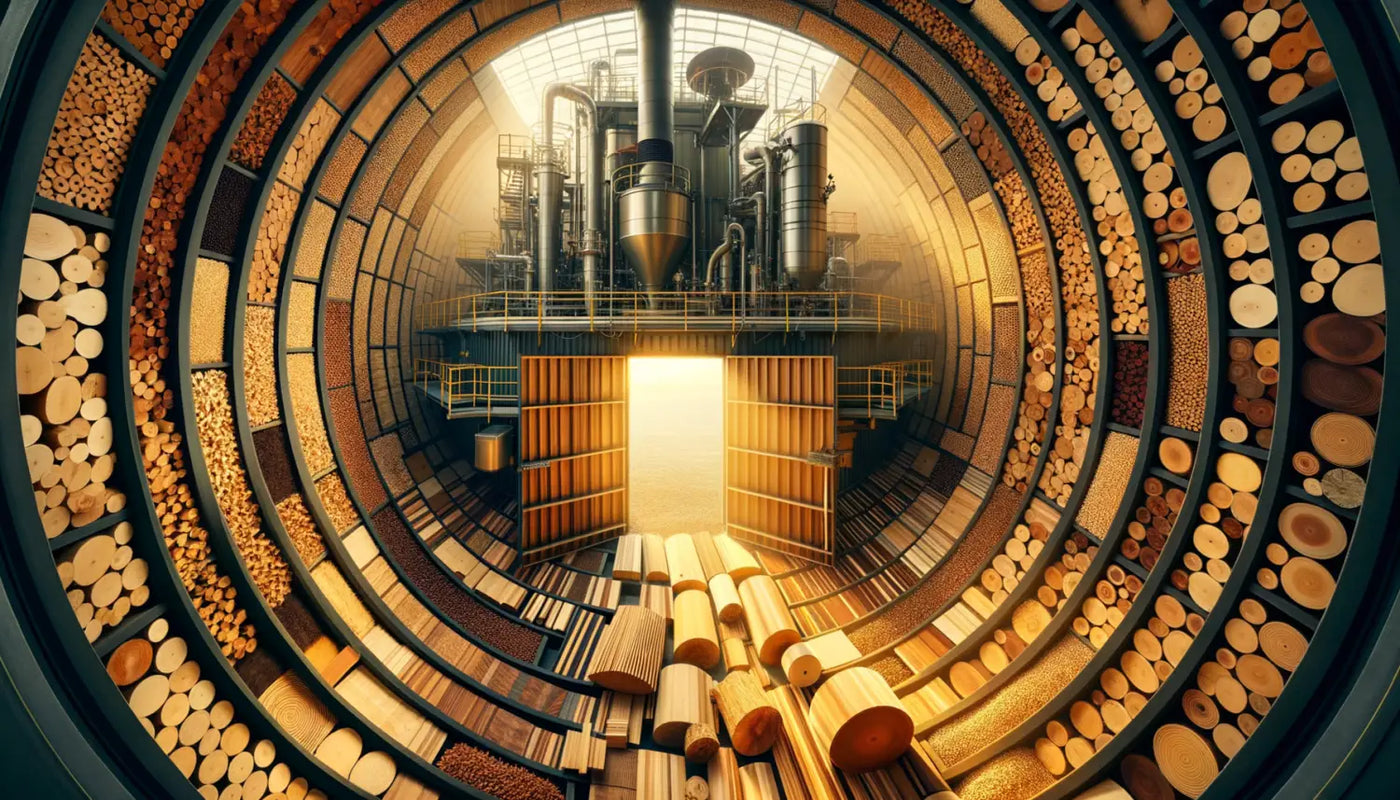

Kiln drying is a controlled wood drying process that facilitates moisture removal from timber. This process uses a specialized chamber known as a kiln, where air temperature, humidity, and circulation are managed meticulously to achieve the desired level of dryness. The purpose of kiln drying is to reduce the wood's moisture content to a level suitable for its intended use, whether it be construction, furniture making, or as firewood. Unlike air drying, which relies on natural weather conditions, kiln drying is a faster and more predictable method of preparing wood.

Importance of Kiln Drying for Wood

The importance of kiln drying lies in its impact on the quality and performance of the wood. Reducing the moisture content helps to:

- Minimize the risk of fungal decay or insect infestation

- Reduce warping, shrinking, and other dimensional changes

- Enhance the wood's strength and structural integrity

- Facilitate better gluing, finishing, and machining properties

Wood that has been kiln dried is generally more stable and less prone to issues related to changes in humidity once in use. This ensures a longer lifespan and better usability for various applications, from construction beams to kiln-dried wood for burning in your fireplace or stove.

Sustainability in Wood Processing

Defining Sustainable Practices

Sustainability in wood processing encompasses a range of practices designed to minimize environmental impact while maintaining economic viability and ensuring social responsibility. Sustainable practices aim to balance ecological concerns with the need for resource utilization. This involves:

- Efficient use of energy and raw materials

- Reducing carbon emissions and pollution

- Ensuring responsible sourcing of timber

- Promoting biodiversity and conservation of natural habitats

In the context of kiln drying, sustainability means adopting techniques and technologies that reduce energy consumption and lower environmental footprints.

Benefits of Sustainability in Kiln Drying

Sustainable kiln drying practices offer numerous benefits:

- Energy Conservation: By using energy more efficiently, kiln operators can cut costs and reduce the strain on non-renewable energy sources.

- Environmental Protection: Lower emissions contribute to cleaner air and less impact on climate change.

- Long-Term Viability: Sustainable practices ensure that timber resources are available for future generations.

- Market Appeal: There is a growing consumer demand for environmentally friendly products, and wood processed sustainably can command a premium in the marketplace.

By integrating sustainability into the kiln drying process, the wood industry can contribute to a greener future while still providing quality products to consumers. Whether it's for hardwood ash logs or construction materials, sustainable kiln drying is an essential aspect of responsible wood usage.

Kiln Drying Process and Energy Consumption

When it comes to transforming timber into a more stable and usable material, the kiln drying process is a key step in the journey. But just how much energy does this process consume? And what can we do to make it more efficient?

How Does Kiln Drying Work?

Kiln drying is a controlled process of reducing the moisture content in wood. This process helps to minimize the risk of shrinkage, warping, and other moisture-related issues in the final product. The steps generally involve:

- Loading the Kiln: The wood is stacked and loaded into the kiln. Proper stacking ensures even airflow and drying.

- Heating: The kiln is then heated to a set temperature, which depends on the type of wood and the desired final moisture content.

- Humidity Control: The kiln's humidity levels are controlled to help draw moisture out of the wood without causing checking or splitting.

- Circulation: Fans are used to circulate the air and promote even drying throughout the kiln.

- Cooling and Conditioning: Once the wood reaches the desired moisture level, it's cooled and conditioned to relieve any drying stresses.

Energy Sources for Kiln Drying

Kiln drying can be quite energy-intensive, typically requiring heat and electricity to run the fans and control systems. Traditional energy sources for kiln drying include:

- Electricity: Powering fans, control systems, and sometimes heating elements.

- Fossil Fuels: Natural gas, propane, or oil are often used to heat kilns.

- Biomass: Wood residues and other biomass can be combusted to provide heat.

Given the energy demands of kiln drying, it's crucial to consider how this phase can be optimized for both economic and environmental benefits.

Optimizing Energy Use in Kiln Drying

Reducing energy consumption within kiln drying operations is not just good for the planet - it's also good for business. Here are some ways in which kiln operators can optimize energy use:

Energy-Efficient Kiln Technologies

Incorporating energy-efficient technologies can significantly lower the kiln's energy use. These include:

- Insulation: A well-insulated kiln retains heat better, reducing energy requirements.

- Heat Recovery Systems: Recycling heat from the kiln's exhaust can improve overall efficiency.

- Variable Speed Drives for Fans: Allows precise control and reduces electricity use when full power isn't needed.

- Automated Control Systems: Smart systems can make real-time adjustments to ensure the kiln is operating at peak efficiency.

Alternative Energy Sources

Embracing alternative energy sources for kiln drying can have a profound impact on sustainability. These alternatives include:

- Solar Power: Solar thermal systems can pre-heat air for kilns, or photovoltaic panels can provide electricity.

- Geothermal: Although less common, geothermal energy can provide consistent heat for drying chambers.

- Waste Heat: Capturing waste heat from other industrial processes can be a cost-effective and green energy source.

Implementing these measures doesn't just reduce carbon footprints; it also cuts down costs, enhancing the sustainability of the wood processing industry. For more detailed insights into energy-efficient kiln drying, check out this article.

By rethinking how we dry wood, we can make a significant impact on the industry's environmental impact. Acting now will help ensure that future generations can enjoy both the beauty of wooden products and a healthy, green planet. For wood enthusiasts keen on sustainable options, consider exploring kiln-dried wood and Swedish fire logs for eco-friendly heating alternatives.

Environmental Impact of Kiln Drying

Emissions and Pollution Considerations

When it comes to kiln drying, it's not just the final product that matters but also the footprint it leaves on the environment. Kiln drying, like any industrial process, can be a source of emissions and pollution. The primary concerns involve the release of volatile organic compounds (VOCs), particulate matter, and carbon dioxide—all of which contribute to air pollution and climate change.

VOCs are emitted during the drying process as the moisture in the wood is heated and begins to evaporate. Some VOCs can cause health problems and contribute to the formation of ground-level ozone, a key component of smog. Particulate matter can affect air quality and health as well, with fine particles posing a risk to respiratory systems. Carbon dioxide emissions are a result of burning fuels to generate the heat necessary for the drying process. This greenhouse gas is a central player in the ongoing narrative of climate change.

Reducing emissions in kiln drying involves:

- Upgrading to more efficient kiln technology that captures or burns off VOCs before they enter the atmosphere.

- Implementing stricter process controls to minimize excess emissions.

- Regular maintenance to ensure kiln systems operate at peak efficiency, reducing the likelihood of unintentional emissions.

Reducing Waste in Kiln Operations

Kiln drying, when not managed properly, can result in considerable waste, from energy losses to material inefficiencies. Waste can occur at multiple stages, from the initial cutting of timber to the final dried product. For example, if wood is over-dried, it can become brittle and unusable. If the kiln isn't operating efficiently, energy is wasted—increasing costs and environmental impact.

Ways to reduce waste include:

- Monitoring moisture content accurately to prevent over-drying or under-drying of wood.

- Recycling heat from kiln exhausts to preheat incoming air, minimizing energy loss.

- Optimizing kiln loads to ensure that each cycle is drying the maximum amount of wood possible, thereby reducing the number of cycles needed.

Sustainable Wood Sourcing

Choosing Sustainable Wood Species

The type of wood being dried in kilns is as important as the drying process itself. The choice of wood species can significantly impact the sustainability of the entire operation. Fast-growing, less resource-intensive species are generally more sustainable options. These species often require less water and can grow in poorer soils, thus having a reduced impact on the environment.

When selecting wood for kiln drying, consider:

- Growth rate: Opt for species that grow quickly and can be harvested sooner.

- Local availability: Choose woods that are locally sourced to reduce transportation emissions.

- Impact on ecosystems: Avoid species whose cultivation or harvesting might harm local ecosystems or biodiversity.

Certifications and Sustainable Forestry

To ensure that the wood you're using or purchasing for your kiln drying needs is sourced sustainably, look for certifications from recognized organizations. These certifications verify that the wood comes from forests managed with conservation and sustainability practices in mind. They often require adherence to a set of standards that consider the long-term health of the forest, the welfare of local communities, and the biodiversity of the area.

Some widely recognized certifications include:

- FSC (Forest Stewardship Council): This international non-profit organization sets standards for responsible forest management.

- PEFC (Programme for the Endorsement of Forest Certification): A framework for the mutual recognition of national or regional forest certification schemes.

Purchasing kiln-dried wood with these certifications can be a part of your commitment to sustainability. It's a simple but effective way to ensure that your wood fuels, be it hardwood ash logs or Swedish fire logs, come from responsibly managed forests.

By focusing on the environmental impact and sustainable wood sourcing in kiln drying, we can help reduce the carbon footprint of this essential process. This not only benefits the planet but also aligns with the growing consumer demand for eco-friendly products and practices. Remember, every step towards sustainability in our industries plays a significant part in the collective effort to protect and preserve our environment for future generations.

Implementing Sustainable Kiln Drying Practices

Sustainability is no longer just a buzzword; it's a practical approach to conducting business with long-term environmental health in mind. For industries that rely on natural resources, such as wood processing, the implementation of sustainable practices is essential. Kiln drying wood, when done sustainably, can reduce the impact on the environment while also offering economic benefits to businesses.

Assessing Your Current Practices

Before you can begin to implement sustainable kiln drying practices, it's crucial to assess your current operations. An assessment should look at various factors including:

- Energy Consumption: How much energy does your kiln use? Is it running at peak efficiency?

- Wood Waste: What happens to wood that is not suitable for sale?

- Emissions: What type of emissions is your kiln producing?

- Wood Sources: Where does your wood come from? Is it from sustainably managed forests?

Here are a few steps to help you assess your current practices:

- Conduct an Energy Audit: Determine the amount of energy your kiln is using and pinpoint areas where you can reduce consumption.

- Analyze Waste Production: Look at how much waste your operations produce and seek ways to repurpose or reduce this waste.

- Review Emission Standards: Check whether your emissions comply with local and national standards and explore ways to reduce your carbon footprint.

- Trace Wood Supply Chains: Ensure that your wood comes from certified sustainable sources.

Strategies for a Greener Kiln Drying Process

Once the assessment is complete, you can implement various strategies to create a more sustainable kiln drying operation. Here are some tactics:

- Upgrade to More Efficient Kilns: Consider investing in newer, more energy-efficient models that could reduce energy consumption and costs in the long run.

- Use Waste Heat Recovery Systems: Implement systems that capture and reuse heat wasted during the drying process.

- Opt for Renewable Energy Sources: If possible, switch to renewable energy sources such as solar or wind power to operate your kilns.

- Implement a Waste Reduction Plan: Find ways to reduce waste, such as using wood offcuts to produce firelighters and kindling or other products.

- Regular Maintenance: Ensure your kilns are well-maintained to operate efficiently and prevent unnecessary energy loss.

These changes may require investment, but they can lead to significant savings and environmental benefits over time. Additionally, they can position your business as a leader in sustainability, which is increasingly important to consumers.

Looking to the Future

As the industry evolves, staying on top of innovations can help your business continue to improve its sustainability.

Innovations in Kiln Drying Technology

The future of kiln drying looks promising with the development of new technologies designed to reduce environmental impact:

- Smart Kilns: Kilns equipped with sensors and automation can optimize the drying process, reducing energy consumption.

- Biomass Energy: Using wood residues as a biomass energy source for kilns is a sustainable option that also reduces waste.

- Heat Pump Technology: Heat pumps can be highly efficient in certain climates, significantly reducing energy usage.

Staying informed about these innovations is vital for future-proofing your business and making continual improvements in sustainability.

The Role of Consumer Choices in Sustainable Practices

The demand for sustainable products is growing. Consumers are becoming more aware of the environmental impact of their purchases and are often willing to pay a premium for sustainably-sourced products. By offering kiln-dried wood from sustainable sources, such as hardwood ash logs that are responsibly harvested, businesses can meet this demand and encourage further industry shifts towards sustainability.

Businesses should also engage with consumers, informing them about the sustainable nature of their products and practices. Education plays a critical role in shaping consumer choices, and informed consumers are more likely to choose products that align with their values.

In conclusion, implementing sustainable kiln drying practices is not only beneficial for the environment but can also lead to economic advantages. By assessing current practices, embracing new technologies, and understanding the role of consumer choices, businesses can contribute to a more sustainable future while also meeting the needs and preferences of their customers.