Introduction to Kiln Drying

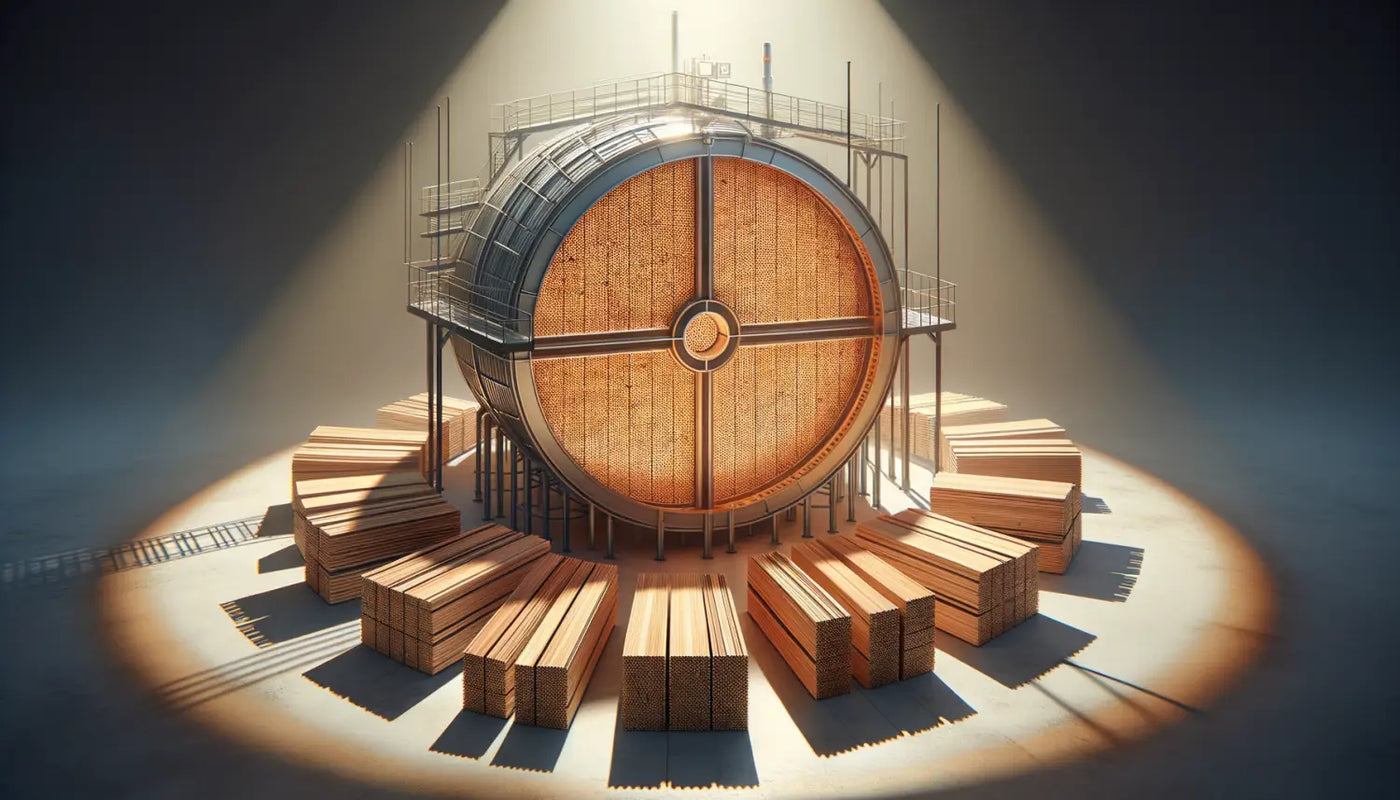

Wood has been a fundamental building block throughout human history, and its preparation is as crucial as its application. One of the most vital processes in wood preparation is drying, and the method of choice for centuries has been kiln drying. So, what makes kiln drying so important?

The Importance of Kiln Drying

Kiln drying is the process of removing moisture from wood, which is essential for several reasons. Firstly, dry wood is stronger and less prone to warping or splitting compared to its wetter counterparts. This ensures the structural integrity of wood is maintained, which is paramount for construction and manufacturing.

Secondly, dry wood is less susceptible to fungal attacks, which can cause decay and compromise the wood's quality. Properly dried wood also has better insulating properties, improving energy efficiency where it is used in construction.

Lastly, kiln drying is an indispensable step for wood that will be used for aesthetic purposes, such as furniture or flooring. It helps to minimize the discrepancies in color and texture, leading to a beautiful, uniform appearance in the final product.

Historical Methods of Wood Drying

Historically, wood drying was a slow and unpredictable process. The simplest method was air drying, where cut timber was stacked outdoors and left to dry naturally. This process could take months or even years, depending on factors like climate and wood species.

Another old technique was solar drying, where wood was placed in structures designed to maximize exposure to sunlight, essentially creating a rudimentary greenhouse effect. Although faster than air drying, this method still relied heavily on weather conditions and was less controlled.

As industries and technologies advanced, there was a growing need for more reliable and quicker drying methods, leading to the development of the first kilns.

Overview of Modern Kiln Drying

With the passage of time and the advent of technology, kiln drying has evolved from simple brick-lined chambers with a heat source to highly sophisticated systems that precisely control the drying environment.

Evolution of Kiln Design

Modern kilns are marvels of engineering, integrating technology to improve efficiency and quality. Early kilns were relatively basic and had limited control over factors like temperature and humidity. The introduction of steam-powered kilns represented a significant leap, offering better control and reducing the drying time.

The design continued to evolve, incorporating electric heating elements, fans for air circulation, and venting systems to control the kiln's atmosphere meticulously. These advancements allowed for a wider range of temperatures and humidity levels, making the process suitable for various wood species and thicknesses.

Differences Between Traditional and Modern Kilns

The differences between traditional and modern kilns are stark. Traditional methods, such as solar and air drying, are largely passive, relying on natural conditions that cannot be controlled. In contrast, modern kilns use a combination of technology and science to actively control the drying process.

One of the most significant differences is the level of control. Modern kilns allow for precise adjustments to temperature, humidity, and airflow. This level of control ensures uniform drying, increased speed, and improved quality of the final product. Additionally, modern kilns often include safety features to minimize the risk of fire, which was a significant concern with earlier kiln technologies.

Modern kilns, with their advanced control systems, offer significant advantages over traditional methods. These include shorter drying times, which enable faster turnaround for projects; consistent quality, which reduces waste; and the ability to dry wood to specific moisture content, crucial for wood's intended use.

For a more in-depth exploration of the basics of kiln drying, you can read this article, which delves into the steps and considerations involved in the process.

The transformative journey from old methods to the modern systems we see today has been driven by the need for efficiency, reliability, and quality. Advancements in kiln technology continue to push the boundaries of what is possible, further refining the art and science of wood drying.

Recent Technological Innovations

With the demand for wood products ever-increasing, the timber industry continues to push forward in its technological journey. It's not just about cutting down trees and shaping them into usable products anymore; it's about doing so efficiently, sustainably, and with a level of precision that only modern technology can provide. Recent advancements in kiln drying technology exemplify this push towards innovation.

Computer-Controlled Systems

Real-time Monitoring

One of the most significant introductions to kiln drying technology has been the development of computer-controlled systems with real-time monitoring capabilities. Gone are the days of manual checks and inconsistent drying results. Kilns are now equipped with sensors and software that provide continuous data on the internal conditions of the kiln, including temperature, humidity, and airflow.

This level of monitoring means that operators can adjust the drying process on the fly, ensuring the wood dries evenly and to the correct moisture content. Real-time data can also be logged for future analysis, helping to optimize the drying process over time.

- **Temperature Sensors**: Track the heat levels inside the kiln.

- **Humidity Sensors**: Monitor the moisture in the air and wood.

- **Airflow Sensors**: Ensure that the air is circulating properly.

Automated Moisture Control

Moisture control is crucial in the kiln drying process. The integration of automated systems has taken the guesswork out of this critical step. These systems adjust the kiln's environment to maintain the ideal moisture levels, responding to the wood's own moisture content which is continuously measured by state-of-the-art sensors.

This automation ensures that the wood dries at an optimal rate - not too quickly to cause cracking and not too slowly to be inefficient. Automated moisture control systems contribute significantly to the quality and consistency of the final product, which you can explore through resources like HSWF's guide on kiln drying.

Heat Recovery Systems

Energy Efficiency

Energy efficiency has become a cornerstone of modern industrial practices, and the kiln drying sector is no exception. Heat recovery systems are now frequently used in kilns to reduce energy consumption. These systems capture and reuse the heat that would otherwise be lost during the drying process.

By recycling this heat, kilns can maintain high temperatures without the need for additional energy input. This not only saves on fuel costs but also reduces the carbon footprint of the drying operation. More details on energy-efficient practices can be found in the HSWF post on energy-efficient kiln drying.

Environmentally Friendly Practices

The introduction of heat recovery systems in kiln technology aligns with the industry's move towards more environmentally friendly practices. By optimizing energy use and reducing waste, these systems help the timber industry minimize its environmental impact. The result is a more sustainable process that aligns with the global efforts to combat climate change and conserve resources.

Upgrades in Kiln Construction Materials

Insulation Improvements

Insulation is a key component of an efficient kiln. Modern kilns benefit from advanced materials that offer superior insulation compared to traditional options. These materials are designed to keep heat in, ensuring that the energy used to heat the kiln is utilized as effectively as possible.

Improved insulation not only enhances energy efficiency but also contributes to a more controlled and stable drying environment. This stable environment is necessary for achieving the desired quality in the final product, particularly for sensitive wood species.

Durability and Longevity Enhancements

The longevity of a kiln is also a critical factor, not just for the economic bottom line but for sustainability. The use of high-grade construction materials in modern kilns means that they are more resistant to the harsh conditions inside the drying chamber, such as extreme heat and humidity.

These materials can withstand the stresses of repeated heating and cooling cycles, reducing the need for frequent repairs or replacements. Durability enhancements lead to longer service life for kilns, which translates to a reduction in the environmental impact associated with manufacturing new kiln components.

In conclusion, the last few years have seen remarkable advancements in kiln drying technology. From the precision and control provided by computer systems to the energy-saving capabilities of heat recovery systems, these innovations represent a leap forward for the timber industry. Likewise, the use of improved materials in kiln construction has resulted in more durable, efficient, and sustainable drying processes. As the need for high-quality timber products rises globally, these technological advancements ensure that the industry can meet demand while also addressing environmental concerns.

Smart Kiln Drying Techniques

In the realm of wood processing, kiln drying is a crucial step that can't be understated. With the surge in technological advancements, smart kiln drying techniques have emerged, revolutionizing how timber is prepared for the market. These sophisticated methods don't just enhance efficiency; they ensure that the wood is dried to perfection, tailored to its unique properties and intended use.

Adaptive Scheduling

A pivotal development in smart kiln drying is adaptive scheduling. Unlike static schedules that don't account for variability in load or ambient conditions, adaptive schedules are dynamic. They can adjust in real-time to factors such as outside humidity levels, temperature fluctuations, and the specific moisture content of the wood entering the kiln. This flexibility is paramount in achieving optimal drying times without compromising the quality of the timber.

Imagine a scenario where a sudden cold snap could potentially extend drying times. An adaptive system will detect this change and might, for example, slightly increase the temperature or adjust the venting strategy to compensate for the external temperature drop. The result? Drying schedules that are responsive and intelligent, leading to consistent outcomes.

Customized Drying Profiles

Customization is the name of the game when it comes to modern kiln drying. No longer is one-size-fits-all an acceptable approach.

Tailored to Wood Species

Each species of wood has its own distinct characteristics, affecting how it should be dried. For example, oak requires a different drying method than pine due to its density and typical moisture content. Modern kilns utilize customized drying profiles that are meticulously designed for each species, considering factors such as thickness, grain pattern, and initial moisture levels.

For instance, a batch of hardwood ash logs might be dried at a lower temperature over a longer period to prevent cracking, whereas a softer wood like pine could tolerate a more robust drying process. These nuanced approaches prevent undue stress on the timber, preserving its structural integrity and appearance.

Optimizing for End-use

The intended end-use of the timber also plays a critical role in how it's dried. Wood destined for fine furniture may have a more conservative drying regimen to minimize the risk of defects that could impair its aesthetic appeal or structural soundness. On the other hand, wood for construction purposes might prioritize speed and efficiency, with a drying profile that's a bit more aggressive, yet still within safe parameters for that application.

By employing precise sensors and control systems, modern kilns can adjust the drying process to the specific requirements of each batch. This tailoring optimizes not just for the type of wood, but for its final destination, ensuring the material is in the best possible condition when it leaves the kiln.

The Role of Big Data in Kiln Drying

Big Data is transforming industries across the board, and kiln drying is no exception. By harnessing massive volumes of data, wood drying processes are entering a new era of precision and predictability.

Predictive Analytics for Maintenance

With the aid of big data, predictive analytics can forecast when a kiln might require maintenance before a breakdown occurs. This proactive approach minimizes downtime and extends the life of the equipment. Sensors can monitor various components of the kiln in real-time, feeding data into advanced algorithms that detect patterns indicative of wear or impending failure.

For example, an unusual vibration pattern in a fan motor might suggest that it's due for replacement. By spotting this early, the kiln operator can schedule maintenance without interrupting the production cycle, avoiding costly emergency repairs and unplanned stops.

Data-Driven Decision Making

Decision-making in kiln operations has also been enhanced through the use of big data. By analyzing detailed records of past drying cycles, including the ambient conditions, wood characteristics, and final moisture content, operators can refine their drying profiles for even better results.

Through machine learning, systems can continually improve, learning from each batch to make smarter adjustments in the future. This ongoing optimization process is invaluable for maintaining high standards of quality and efficiency in wood drying operations.

In the age of information, data reigns supreme, and kiln drying technology is no exception. By leveraging the power of adaptive scheduling, customized drying profiles, and big data analytics, the timber industry is poised to continue its trajectory of innovation and excellence.

Benefits of Modern Kiln Drying

Increased Productivity

The advancements in kiln drying technology have significantly boosted productivity levels within the timber industry. Modern kilns are designed to be more efficient and faster than traditional methods, allowing for larger quantities of wood to be processed within the same timeframe. This efficiency is partly due to the introduction of computer-controlled systems that monitor and adjust the drying conditions in real time. Manufacturers can now dry wood to the desired moisture content more quickly, ensuring that the wood is ready for market sooner, thus increasing their potential revenue.

One of the key factors contributing to increased productivity is the precise control over the drying process. By eliminating much of the guesswork and manual intervention that was prevalent in older drying systems, today’s kiln operators can optimize the drying schedule based on the type of wood and its intended use. For example, hardwood ash logs require a specific drying regimen to preserve their high combustion quality when used as firewood. By using a modern kiln equipped with the latest technology, producers can ensure a consistent and efficient drying process that meets the high standards for such premium products.

Moreover, with improved insulation materials and construction techniques, modern kilns minimize heat loss which translates to less energy required to maintain the optimal drying temperature. The reduction in energy consumption not only means less operating costs but also the ability to run more cycles over a given period, thus increasing overall productivity.

Quality Improvement in Final Product

Uniformity in Drying

One of the most significant advantages of modern kiln drying technology is the ability to achieve uniform drying across all pieces of wood. In the past, inconsistencies in the drying process could lead to some boards drying faster than others, resulting in varying moisture content and potential quality issues. Now, with advanced systems in place, the conditions inside the kiln can be finely tuned to ensure that each piece of wood dries evenly.

Uniform drying is particularly important when the wood is destined for use in construction or fine woodworking where precision and reliability are critical. Consistent moisture content throughout the wood means that it is less likely to warp, shrink, or crack once it leaves the kiln, which increases the value of the final product.

Reducing Defects

Advanced kiln drying technology not only improves the uniformity of the drying process but also significantly reduces the occurrence of defects. Defects such as checking, honeycombing, and case-hardening can diminish the functional and aesthetic value of wood. Modern kilns equipped with precise humidity and temperature controls can minimize these issues by creating the ideal environment for drying specific types of wood.

Through automated moisture control systems, the rate of moisture removal can be carefully managed to prevent rapid changes that might cause stress and damage to the wood. This meticulous approach to drying results in a higher quality product that meets the strict standards of consumers and professionals in the industry.

Future Outlook on Kiln Drying Technology

Sustainable Practices and Renewable Energy

The kiln drying industry is increasingly moving toward sustainable practices, with a strong focus on reducing carbon footprints and utilizing renewable energy sources. Advancements in kiln design now often incorporate materials and systems that are more energy-efficient and environmentally friendly. For instance, heat recovery systems are now more commonly used to capture and reuse heat that would otherwise be lost, thus reducing energy waste and operational costs.

In the future, we can expect to see further integration of renewable energy sources such as solar or biomass to power kilns. These advancements will not only benefit the environment but also offer long-term cost savings for businesses as they become less dependent on fossil fuels. Embracing sustainable practices is not only a moral imperative but also a strategic business decision that can enhance the reputation and profitability of companies in the industry.

The Potential of IoT and Automation in Kiln Drying

The Internet of Things (IoT) and automation are poised to revolutionize the kiln drying industry. By integrating sensors, connectivity, and automated systems into kilns, operators can gain even more precise control over the drying process. IoT devices can provide real-time data on the wood's condition inside the kiln, allowing for adjustments to be made instantly, reducing the chance of human error, and ensuring optimal drying conditions at all times.

The potential of automation extends beyond real-time monitoring to predictive maintenance and adaptive scheduling, which can anticipate the needs of the kiln and schedule maintenance before breakdowns occur. This proactive approach can reduce downtime and extend the lifespan of the kiln, leading to greater efficiency and cost savings.

In the near future, IoT and automation technologies will likely become standard features in kiln drying, further pushing the boundaries of what is possible within the industry. This integration of technology will pave the way for even more efficient, reliable, and high-quality wood drying processes that can adapt to the dynamic demands of the market.

Summary and Conclusion

Recap of Key Advancements

Throughout this article, we've delved into the numerous advancements that have transformed kiln drying from a rudimentary process to a sophisticated, precision-driven operation. Key innovations such as computer-controlled systems, heat recovery, improved construction materials, and smart drying techniques have all played a role in improving productivity and the quality of the final product.

The Impact on the Timber Industry

The impact of these advancements on the timber industry cannot be overstated. Increased efficiency and improved wood quality translate to a more competitive market, where businesses can thrive by offering superior products. The adoption of sustainable practices and renewable energies is not only beneficial for the environment but also for the long-term viability of the industry. As we look to the future, with the potential of IoT and automation, it's clear that the kiln drying process will continue to evolve and play a critical role in the success of the timber industry.