Introduction to Kiln Drying Pine

The Importance of Proper Drying

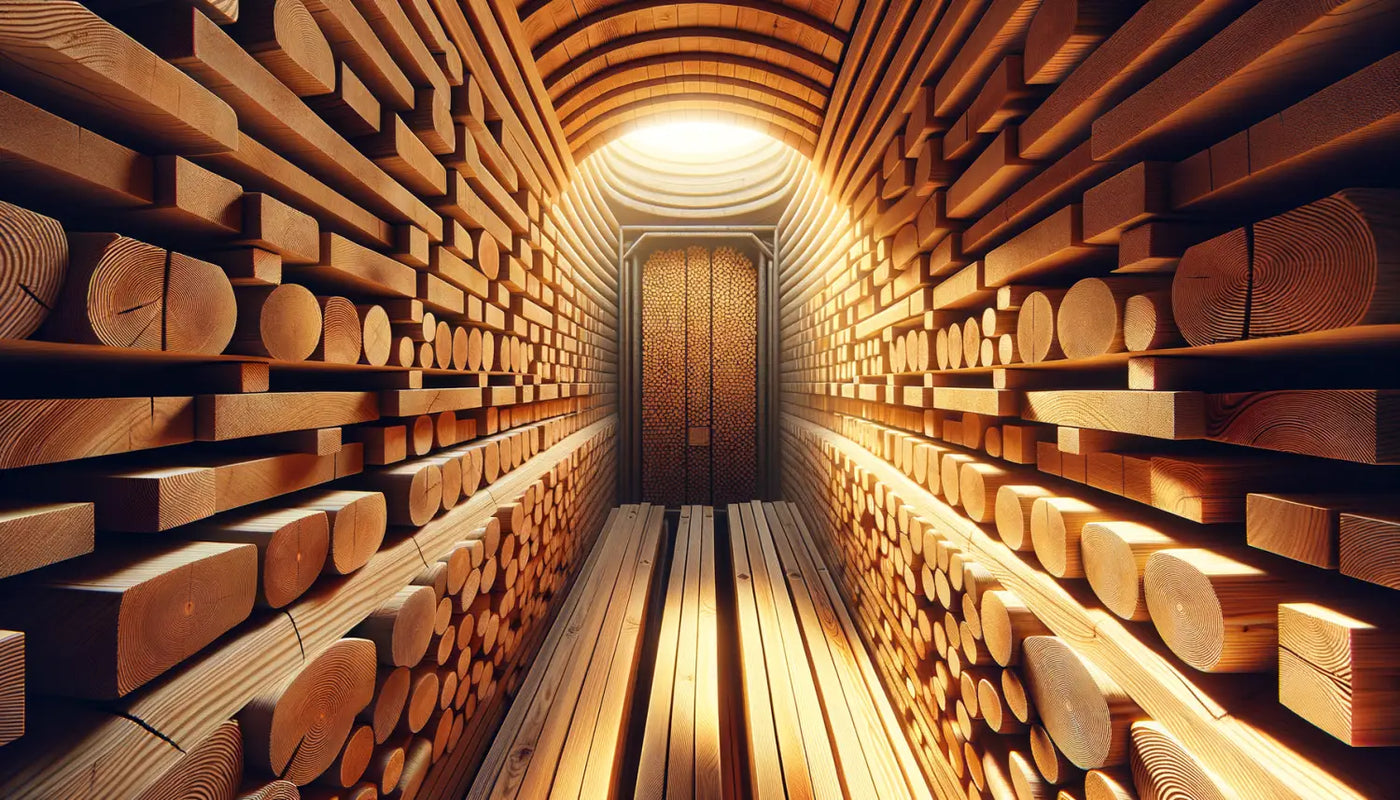

When it comes to working with pine, one crucial step that can't be overlooked is the drying process. Proper drying is essential because it stabilizes the wood, making it less prone to warping, cracking, and other deformities that can occur as it adjusts to changes in humidity and temperature. Kiln drying pine is a controlled method that carefully reduces the moisture content of the wood to a level appropriate for its intended use, often around 8-12% for interior applications.

The process not only ensures that the pine wood maintains its structural integrity but also enhances its natural beauty and prepares it for staining, painting, or other finishes. For those in the construction and carpentry industries, understanding and executing the drying process competently is key to delivering a quality product that stands the test of time.

Characteristics of Pine Wood

Pine is a softwood that's widely available, relatively affordable, and commonly used in a variety of applications, from construction to furniture making. Here are some characteristics of pine wood that make kiln drying a vital step:

- Resinous: Pine has a high sap content which can cause issues if not properly dried.

- Density Variations: With its mixture of earlywood and latewood, pine can dry unevenly if not handled correctly.

- Knots and Imperfections: These natural features can affect how the pine responds to the drying process.

The unique properties of pine require a tailored approach to kiln drying to prevent defects such as checking (cracks along the wood's growth rings) and case-hardening (stress caused by uneven drying rates between the surface and core of the wood).

Understanding the Kiln Drying Process

Stages of Kiln Drying

Kiln drying involves several stages that gradually reduce the moisture content of the wood:

- Pre-drying: Pine is often air-dried to remove the free water (the water in the cell cavities) before kiln drying.

- Loading: Boards are stacked and loaded into the kiln, careful to allow proper air circulation around each board.

- Heating: The kiln is slowly heated to the target temperature, which can vary depending on the thickness and type of pine.

- Drying and Humidity Control: Constant monitoring and adjustment of temperature and humidity levels are required to dry the wood evenly.

- Conditioning: Once the desired moisture level is reached, the pine is conditioned to relieve any stresses and equalize moisture content throughout each piece of wood.

- Cooling: The kiln is cooled down, and wood is left to acclimatize before being removed.

Each stage is critical, and understanding the timing and conditions for each will ensure that the pine dries uniformly and is ready for use without additional issues.

Equipment Used for Drying Pine

The primary equipment used for drying pine in a kiln includes:

- Kiln Chamber: An insulated space where the wood is placed for drying.

- Heating System: Usually consists of boilers, steam coils, or gas heaters to control the temperature.

- Fans: Used to circulate air and promote even drying.

- Venting System: Controls the humidity levels by releasing moist air and bringing in dry air.

- Moisture Meters: Devices to measure the moisture content of the wood during the drying process.

- Control Systems: Automated systems to regulate temperature, humidity, and airflow within the kiln.

By employing the right equipment and maintaining its efficiency, kiln operators can ensure that each batch of pine is dried to perfection, ready for its next stage of use. For more on the specifics of equipment used in kiln drying and how it functions, you might find our articles on temperature control in kiln drying and humidity in wood drying quite informative.

Preparing Pine for Drying

Before you even think about firing up the kiln, it's essential to prepare your pine wood correctly. The preparation stage is critical to ensure that the drying process goes smoothly and that the end product is of high quality. Let's dive into the key steps you need to take.

Assessing Moisture Content

The moisture content (MC) of wood is the amount of water present relative to the dry mass of the wood. It's crucial to measure the MC of your pine before drying because it determines how much drying is needed and affects the kiln schedule that you'll use. The target is to reach an equilibrium moisture content (EMC) specific to the wood's intended use.

Use a moisture meter to assess the MC. Here are two types of meters:

- Pin-Type Moisture Meters: These have two pins that penetrate the wood surface, measuring electrical resistance which changes with moisture content.

- Pinless Moisture Meters: These use an electromagnetic sensor to scan the surface without penetrating it, which is ideal for finished products.

For accurate readings, test several boards and at different spots, especially near the ends and middle of the boards. This will give you a good average reading of the batch.

Trimming and Sizing Tips

Before the pine can be dried, it needs to be properly trimmed and sized. Follow these tips for best results:

- Trimming: Remove any excess parts of the log that won't be used. This includes trimming off branches or any parts with significant damage.

- Sizing: Cut the wood to the required dimensions before drying. Consider the final use of the wood and allow for some shrinkage, which occurs during drying.

- Stickering: Place stickers, which are small pieces of wood, between the lumber layers. This allows air to flow around all sides of the boards and assists in even drying.

- Uniformity: Ensure all your stickers are of uniform thickness and aligned vertically to prevent warping.

Setting Up the Kiln

Getting the kiln ready is just as important as the preparation of the wood itself. Here's what to keep in mind:

Temperature and Humidity Control

Controlling the temperature and humidity within the kiln is vital for successful drying. Pine generally dries well at temperatures between 65°C to 82°C, with relative humidity (RH) levels tailored to the drying phase. As the wood dries, the RH is usually lowered to help pull more moisture from the wood.

To set up your kiln for pine, consider the following:

- Start with a higher RH: Begin with a higher RH to avoid stressing the wood.

- Gradually increase temperature: As the wood dries, increase the temperature within the kiln gradually to avoid defects like checking or warping.

- Use vents: Properly use vents to control the kiln's atmosphere and remove moist air.

For more detailed insights on temperature control during kiln drying, check out this blog post.

Loading the Kiln Efficiently

How you load the kiln can significantly affect the drying process. Here's how to do it right:

- Even spacing: Ensure that there is even spacing between boards for uniform airflow.

- Vertical alignment: Align the stickers from one layer to the next to prevent uneven drying and warping.

- Load capacity: Don't overload the kiln. Each piece needs enough space for the air to circulate around it.

- Place a sample: It's a good practice to place a sample piece with a moisture meter probe in it to monitor the drying process closely.

After loading the kiln, double-check the settings, and you're ready to start the drying cycle. Remember to refer to kiln manufacturer guidelines and industry best practices for specific details on kiln loading and operation.

By carefully preparing your pine for drying and meticulously setting up your kiln, you're setting yourself up for success. The right start can help minimize defects, save energy, and produce high-quality dried pine suitable for various applications. If you're looking to buy kiln-dried wood or need additional supplies for firemaking like Swedish fire logs, firelighters, or kindling, feel free to explore options at HSWF. And for those looking to learn more about wood fuels, including hardwood ash logs, check out their collection here.

Monitoring the Drying Process

When kiln drying pine, meticulous monitoring is paramount to ensure the highest quality of the finished product. Pine, being a softwood, is susceptible to various drying defects if not carefully controlled during the kiln drying process. By monitoring the wood’s moisture content and the kiln’s environment, you can minimize these risks and achieve uniformly dried lumber.

Using Moisture Meters

To ensure pine wood dries to the desired moisture content, the use of moisture meters is essential. These devices come in two main types: pin-type and pinless. Pin-type moisture meters measure the electrical resistance between two pins inserted into the wood, which correlates to the wood's moisture content. Pinless meters use electromagnetic waves to measure moisture without damaging the wood's surface.

When selecting a moisture meter, consider the following factors:

- Accuracy: Look for a meter with a proven track record of accuracy. A small margin of error can translate to significant quality issues in the finished product.

- Calibration: Ensure that the meter is calibrated specifically for pine, as different species have different electrical properties affecting the readings.

- Depth of Measurement: Different projects may require different penetration depths. For thicker lumber, a deeper reading might be necessary to accurately assess internal moisture content.

Utilizing moisture meters effectively involves:

- Taking readings from several areas of the board to get an average moisture content.

- Monitoring the decrease in moisture content over time to ensure the wood is drying uniformly.

- Comparing readings from boards at different kiln locations to identify any potential uneven drying.

Troubleshooting Common Issues

Kiln drying pine is not without its challenges, and various issues may arise during the process. By recognizing common problems, you can take timely actions to rectify them.

Case Hardening: This occurs when the outside of the wood dries faster than the inside, creating internal stresses. To prevent this, ensure that the drying schedule is not too aggressive for the thickness and species of the pine being dried.

Honeycombing: Internal checks or cracks can develop if the wood is dried too quickly. Maintaining a consistent and appropriate temperature and humidity within the kiln is crucial to avoid honeycombing.

Warping: Boards may warp if not stacked correctly or if there are fluctuations in the drying conditions. Make sure the kiln is loaded properly, and the conditions remain stable throughout the process.

Sticker Stain: If the stickers (the spacers between the boards) are not dry or chemically compatible with pine, they can cause discoloration. Use dry, resin-free stickers to prevent this issue.

To troubleshoot effectively:

- Regularly check for visual signs of drying defects.

- Adjust the kiln settings as needed according to the stage of drying and the response of the wood.

- If defects are detected, it may be necessary to adjust the drying schedule or even recondition the affected lumber.

Finishing the Dried Pine

After the pine has reached the desired moisture content, it's crucial to condition the wood to relieve any residual stresses and prevent future warping or distortion.

Conditioning the Wood

Conditioning involves restoring a small amount of moisture to the outer layers of the wood to balance the moisture gradient between the interior and exterior. This process, typically done at the end of the kiln cycle, can prevent cracking and splitting caused by too rapid drying.

Here's how to condition pine effectively:

- Increase the humidity in the kiln for a short period, usually a few hours, depending on the kiln size and wood thickness.

- Monitor the wood to ensure that the reintroduction of moisture is even and controlled.

- After conditioning, slowly cool down the kiln before removing the wood to avoid any sudden temperature changes that could introduce new stresses.

Storage and Handling Best Practices

Proper storage and handling of kiln-dried pine are critical to maintain its quality. Store the wood in a cool, dry place and protect it from direct sunlight and moisture. If the wood will not be used immediately, consider wrapping it in a breathable material to prevent dust accumulation and minor variations in moisture content due to changes in ambient humidity.

Here are some storage tips:

- Stack the wood flat with spacers between layers to allow air circulation.

- Avoid ground contact by placing the stacks on pallets or racking.

- If the wood is stored outside, cover it with a waterproof but breathable tarp.

By following these guidelines, the quality of the dried pine can be preserved until it’s ready for use in construction, carpentry, or any other intended application. Remember, the final quality of the kiln-dried pine is not only about the drying process but also about how well the wood is conditioned and stored afterwards.

Ensuring Quality and Consistency

Quality and consistency are paramount in the kiln drying process for pine. Achieving the optimal moisture content without damaging the wood requires a systematic approach. Let's delve into how you can maintain high standards throughout your drying operations.

Record-Keeping Strategies

Good record-keeping is essential in any kiln drying operation. It allows you to track the progress of each batch, understand what conditions work best, and make informed decisions for future drying cycles. Here are some guidelines to help you manage your records effectively:

-

Batch Identification: Assign a unique identifier to each batch of pine that goes into the kiln. This could be a date, a sequential number, or a code that reflects the source and type of wood.

-

Drying Parameters: Document the temperature, humidity, and airflow settings for each cycle. Note any adjustments made during the process.

-

Moisture Content Logs: Use a moisture meter to regularly check the moisture content of the pine at various stages of drying. Record these readings with the corresponding times and dates.

-

Observations and Adjustments: Keep detailed notes on any peculiarities observed during drying—like unusual wood behavior or equipment hiccups—and the steps taken to address them.

-

Final Quality Checks: After the pine has been conditioned and cooled, make a final assessment of its moisture content and overall quality. Note any defects and whether they can be attributed to the drying process.

By keeping comprehensive records, you are establishing a rich data source that can help you refine your drying techniques and maintain a high standard of quality.

Regular Equipment Maintenance

The reliability of your kiln is largely dependent on the condition of the equipment. To prevent downtime and ensure that each batch of pine is dried evenly and effectively, you must maintain your kiln regularly. Here's a checklist to keep your equipment in top shape:

-

Daily Inspections: Check for any obvious signs of wear or damage to the kiln's structure and components.

-

Cleaning: Remove sawdust and debris that could obstruct airflow or become a fire hazard.

-

Calibration: Periodically calibrate sensors and controls to ensure accurate temperature and humidity readings.

-

Service Components: Replace or service components like fans, heating coils, and humidifiers as recommended by the manufacturer.

-

Professional Audits: Schedule annual inspections by a qualified technician to assess the kiln's overall health and performance.

Regular maintenance not only prevents unexpected breakdowns but also ensures that your kiln operates at peak efficiency, saving energy and reducing costs in the long run.

Advantages of Properly Dried Pine

Proper kiln drying of pine offers numerous benefits, particularly for users in construction and carpentry, as well as for the longevity and quality of the final products.

Benefits for Construction and Carpentry

For builders and carpenters, pine that has been correctly dried in a kiln is a pleasure to work with. It offers several advantages:

-

Stability: Properly dried pine is less likely to warp, twist, or cup once installed, ensuring structural integrity and aesthetic appeal.

-

Uniformity: Consistent moisture levels throughout the wood make it easier to cut, shape, and join, leading to a smoother construction process.

-

Weight: Dried pine is lighter, making it easier to handle and transport, potentially reducing labor and shipping costs.

- Adhesive and Finish: Dried pine accepts adhesives, stains, and finishes more evenly, resulting in a superior final product.

Longevity and Quality of Final Products

End-users also reap the benefits of kiln-dried pine in the longevity and quality of the wood in their products:

-

Durability: A lower moisture content means that pine is less prone to decay and insect infestation, extending the life of the product.

-

Dimensional Stability: Kiln-dried pine maintains its dimensions better over time, crucial for joinery and fittings that need to remain tight.

-

Aesthetic Quality: The wood’s appearance is preserved, with fewer defects such as cracks or splits, ensuring it looks good for years to come.

By focusing on the proper kiln drying of pine, suppliers and craftspeople can offer a high-quality product that stands the test of time and satisfies the needs of discerning customers.

Conclusion and Next Steps

Summarizing Key Points

In conclusion, kiln drying pine is a delicate process that, when executed properly, ensures the highest quality of wood for various uses. Maintaining quality and consistency is crucial and can be achieved through diligent record-keeping and regular equipment maintenance. The advantages of properly dried pine are evident in the benefits it brings to construction and carpentry, as well as the longevity and quality of the final products.

Additional Resources and Expert Tips

For those looking to dive deeper into the intricacies of kiln drying, there are a wealth of resources available. You can learn more about the specifics of kiln drying and the best ways to store and handle wood from our blog posts. Also, consider exploring Swedish fire logs for a unique approach to burning wood, or expand your knowledge about firelighters and kindling to ensure your wood burns efficiently.

By staying informed and attentive to the details of the kiln drying process, you'll be well-equipped to produce pine wood that is unmatched in quality and durability, meeting the needs of the most exacting customers and projects.