Understanding Your Kiln

The Importance of Regular Kiln Inspections

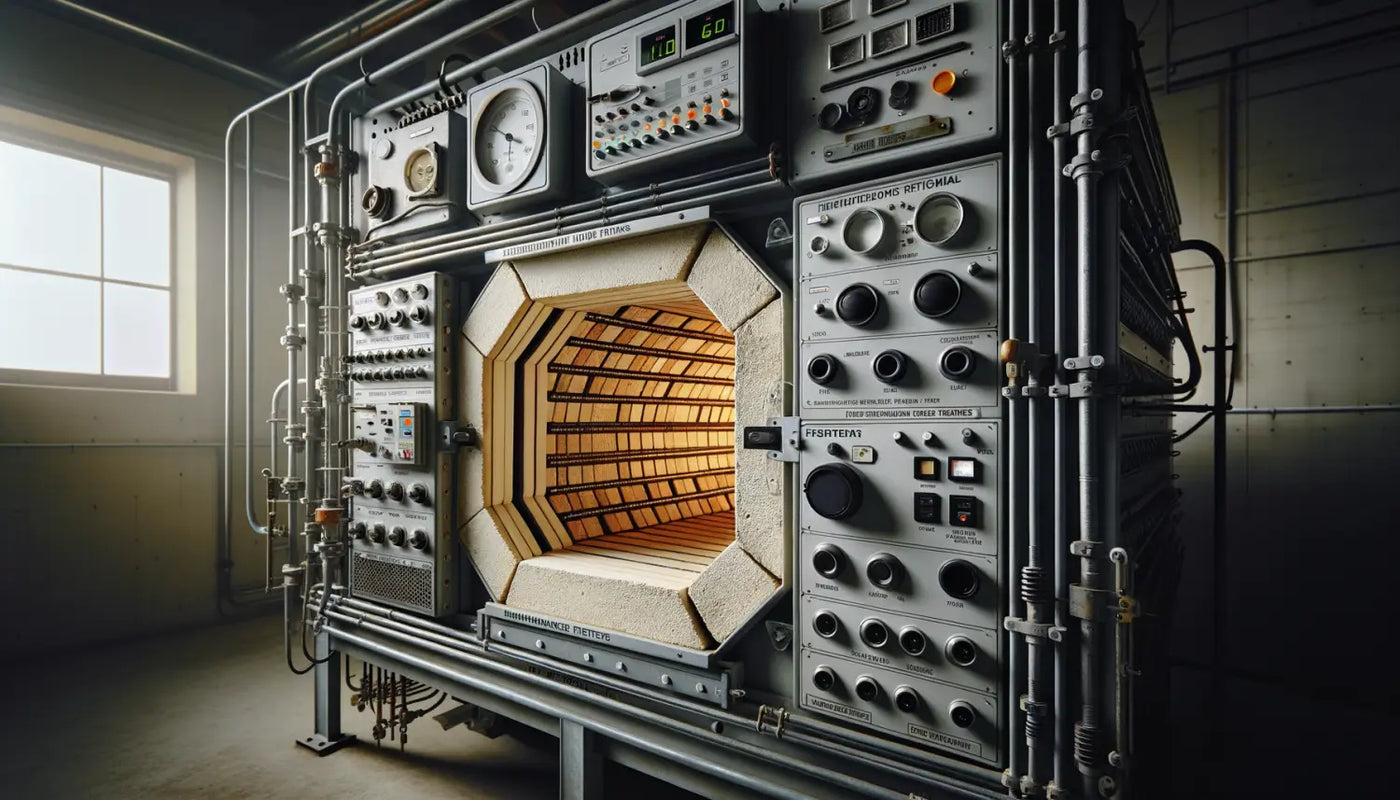

A kiln is an essential tool in the woodworking and ceramics industries, playing a pivotal role in the drying and firing processes. To ensure your kiln operates efficiently and safely, regular inspections are crucial. Much like a car needs consistent servicing to run smoothly, a kiln requires the same level of care to maintain performance and prolong its lifespan.

Regular inspections can help:

- Prevent unexpected breakdowns: Catching issues early can prevent minor problems from escalating into major malfunctions.

- Ensure consistent results: Regular maintenance helps maintain the kiln's ability to evenly distribute heat, which is vital for quality outcomes.

- Enhance safety: Kilns are high-temperature machines that can pose safety risks if not properly maintained.

- Save money: Proper upkeep can save costs in the long run by avoiding expensive repairs or replacements.

Key Components and Their Functions

It's beneficial to familiarize yourself with the key components of your kiln. This knowledge aids in understanding what to look for during inspections and when performing maintenance tasks.

- The shell: This is the exterior part of the kiln, which encases the interior components and holds in the heat.

- Insulation: Located within the walls of the kiln, insulation helps maintain temperature and energy efficiency.

- Heating elements: These are responsible for generating heat within the kiln. They can wear out over time and may need replacement.

- Kiln shelves and posts: These provide support for the items being dried or fired inside the kiln.

- Kiln controller: An electronic device that regulates the temperature and duration of the kiln's heating cycles.

- Thermocouples: Sensors that measure temperature and provide feedback to the controller.

- Vent systems: These remove fumes and help control the atmosphere within the kiln.

Pre-Maintenance Preparations

Safety Precautions to Follow

Before you start any maintenance on your kiln, it's imperative to take the necessary safety precautions to avoid injuries. Here are some guidelines:

- Disconnect power: Always switch off and unplug the kiln from its power source before starting any work.

- Allow cooling: Ensure the kiln is completely cool before you begin. It may retain heat for several hours after use.

- Wear protective gear: Use heat-resistant gloves, safety goggles, and a mask to protect against dust and debris.

- Keep a clean workspace: Ensure the area around the kiln is free from flammable materials and clutter.

Scheduling Maintenance Downtime

To minimize disruption to your workflow, plan maintenance during downtime. Consider the following:

- Check usage schedules: For businesses, schedule maintenance when the kiln is typically not in use, such as after hours or during slower production periods.

- Inform users: If multiple people use the kiln, make sure they are aware of the maintenance schedule.

- Record maintenance: Keep a log of all maintenance activities to track the kiln's history and plan future inspections.

Regular inspections and maintenance are part of the essentials for achieving optimal results in kiln drying. By understanding the importance of these activities and preparing adequately, you can ensure your kiln continues to operate at its best. For further reading on the basics of kiln drying, you can explore here, and for more detailed steps on kiln drying processes, click here.

Cleaning and Inspection

Routine Cleaning Procedures

A clean kiln is fundamental to its operation and longevity. Regularly removing sawdust, debris, and any other foreign materials ensures that your kiln functions efficiently. Below are key steps to ensure your kiln remains in prime condition:

-

Sweep and Vacuum: Begin by sweeping the floor around the kiln to eliminate any accumulated dirt. Use a vacuum cleaner with a nozzle attachment to extract sawdust and small particles from the kiln's interior, especially in hard-to-reach corners.

-

Wipe Down Surfaces: With a damp cloth, wipe down all surfaces to remove any lingering dust. Avoid using water inside the kiln, as excess moisture can affect its performance.

-

Clean the Vents: If your kiln is equipped with vents, ensure they are clear of obstructions. A clogged vent can reduce air circulation and hinder the drying process.

- Air Out the Kiln: After cleaning, leave the kiln door open to air out the interior, which helps to prevent musty odours and mildew growth.

Inspecting the Kiln's Interior

The interior of the kiln demands a thorough inspection to spot any signs of wear or damage. Look for:

-

Cracks in the Walls or Floor: These can indicate structural problems that might need professional attention.

-

Discolouration: This could suggest overheating or inefficiencies in the drying process.

-

Damp Spots: Moisture presence could mean there are leaks or condensation issues that need to be addressed.

It's vital to record any abnormalities you find during the inspection to track changes over time or to discuss with a maintenance professional if needed.

Checking the Condition of Kiln Shelves and Posts

Your kiln shelves and posts are critical for supporting the wood during the drying process. They should be inspected for:

-

Cracks or Chips: Damaged shelves can collapse, damaging the kiln and the wood.

-

Warping: This can occur over time due to heat exposure and might make the shelves unstable.

-

Glaze or Debris Build-up: Remove any glaze drips or debris to ensure even heat distribution. Use a kiln shelf scraper if necessary.

Replace any shelves or posts that show significant wear or damage to maintain safety and effectiveness.

Mechanical and Structural Integrity

Monitoring Kiln Supports and Stands

The kiln's supports and stands bear the weight of the entire structure, so they must be robust and stable. Inspect these for:

-

Rust or Corrosion: This can weaken the metal and lead to structural failure.

-

Loose Bolts or Fittings: Make sure that all connections are secure to prevent any movement or shifting of the kiln.

-

Signs of Wear: Look for any bending or warping in the metalwork that could compromise the kiln's integrity.

Regular checks and maintenance of the supports and stands are critical to avoid potential accidents or malfunctions.

Inspecting and Tightening All Hardware

Kilns are equipped with various hardware components, such as hinges, latches, and fasteners. Keep them in working order by:

-

Tightening Bolts and Screws: Loose fittings can lead to heat loss and inefficiency.

-

Lubricating Moving Parts: Apply an appropriate high-temperature lubricant to hinges and latches to keep them functioning smoothly.

-

Checking for Wear: Replace any components showing signs of excessive wear to prevent failure during operation.

A proactive approach to maintenance will minimize the risk of unexpected downtime and prolong the life of your kiln. Remember that proper upkeep is not only about preserving the kiln itself but also about ensuring the quality of the kiln-dried wood that comes out of it. By adhering to a comprehensive cleaning and inspection routine, you can maintain the reliability and performance of your kiln, ensuring that it operates safely and efficiently for many years to come.

Heating Elements and Electrical Systems

Maintaining your kiln's heating elements and electrical systems is crucial to ensure that the drying process goes smoothly and efficiently. Regular checks and maintenance can prevent unexpected downtime and preserve the lifespan of your kiln.

Checking and Replacing Worn Heating Elements

Heating elements are the heart of a kiln's operation. Over time, these elements can wear out or break, leading to uneven heating and potential damage to the kiln’s interior and the products being dried. It is important to visually inspect the heating elements regularly for any signs of damage, distortion, or discolouration.

When inspecting the elements:

- Turn off and unplug the kiln.

- Allow the kiln to cool down completely.

- Remove any kiln furniture and products.

- Visually check the elements for any signs of wear or damage.

If you notice any issues, it may be time to replace the elements. It's generally recommended to replace all elements at the same time to ensure even heating. For detailed instructions on replacing heating elements, refer to your kiln’s manual or contact the manufacturer for guidance.

Maintaining Optimal Electrical Connections

The electrical connections in your kiln must be kept in good condition to ensure safety and proper functioning. Loose connections can lead to arcs and sparks, which can cause damage or even start a fire. During each maintenance session:

- Turn off the power to the kiln and lockout the switch to prevent it from being turned on.

- Check all connections for tightness.

- Look for signs of corrosion or overheating, such as discoloured wires or terminals.

- Clean and tighten connections, if necessary.

High-quality, non-corrosive contact cleaner can be used to clean electrical contacts, but ensure that it is appropriate for use with the specific materials in your kiln.

Troubleshooting Common Electrical Issues

Occasionally, you may encounter electrical issues with your kiln, such as the kiln failing to reach temperature or elements not heating evenly. Before calling a professional, there are a few troubleshooting steps you can take:

- Check the kiln’s fuse or circuit breaker to ensure they have not tripped.

- Inspect the power supply to make sure it matches the requirements of your kiln.

- Look for any visible damage to the elements, thermocouples, or wiring.

- Test the continuity of the heating elements using a multimeter.

If you’re not comfortable working with electrical components, or if the problem persists, seek the assistance of a qualified kiln technician.

Temperature Accuracy and Control

For the best drying results, maintaining an accurate temperature control system is essential. This ensures that your wood products, such as those found at HSWF, dry evenly and without defects.

Calibrating Kiln Controllers and Pyrometers

Calibration is the process of ensuring that your kiln’s temperature readings are accurate. Over time, the devices that measure and regulate the kiln’s temperature, such as controllers and pyrometers, can drift from their calibrated settings.

To calibrate your kiln:

- Refer to the manufacturer’s guidelines for your specific model.

- Use a known reference, like a test cone or a calibrated thermocouple, to compare against the kiln’s temperature readings.

- Adjust the kiln’s controller or pyrometer settings according to the difference found.

Regular calibration ensures that the temperature inside your kiln matches the set point on your controller, resulting in more consistent drying and fewer defects in your wood.

Assessing and Maintaining Temperature Uniformity

Uniform temperature distribution is vital for the quality of the drying process. Temperature variations can cause differential drying rates, leading to stress and defects within the wood. To assess temperature uniformity:

- Use multiple thermocouples placed at different points in the kiln.

- Run the kiln at a steady temperature and log readings from different locations.

- If you notice significant variations, this could indicate issues with the airflow, heating element distribution, or kiln design.

To maintain temperature uniformity:

- Ensure that the kiln’s baffles and vents are properly adjusted.

- Regularly clean fans and heating elements to allow for consistent airflow.

- Check that the kiln load is evenly distributed and not blocking airflow.

By keeping a close eye on these elements and adhering to a regular maintenance routine, you can help ensure the even drying of products such as those found in HSWF's Swedish Fire Logs and Hardwood Ash Logs collections.

Following these steps in kiln maintenance can help extend the life of your kiln, improve its performance, and ensure the highest quality drying process for your wood products. Remember, if you come across an issue that seems daunting or beyond your expertise, don’t hesitate to seek professional assistance.

Preventive Measures and Best Practices

Preventive measures are the cornerstone of kiln longevity and performance. A proactive approach to kiln maintenance can save you time, money, and avert potential disasters. Here are some best practices that can help keep your kiln in top condition.

Implementing a Regular Maintenance Schedule

Consistency is key when it comes to maintaining your kiln. By establishing a regular maintenance schedule, you ensure that all components of the kiln are inspected and serviced routinely, which helps in identifying issues before they become serious problems. It's advisable to consult your kiln's manual for the manufacturer's recommended maintenance intervals, but here's a generic timetable to get you started:

- Daily: Check for any noticeable damage or obstructions and verify the correct operation of the kiln's controller.

- Weekly: Clean the kiln’s interior and exterior, removing any debris that could affect performance.

- Monthly: Inspect heating elements, electrical connections, and structural components.

- Annually: Conduct a thorough inspection and servicing by a professional if needed.

Remember to log all maintenance activities. Keeping records will help you to track the kiln's condition over time and make more informed decisions about its upkeep.

The Role of Lubrication in Kiln Maintenance

Lubrication is an essential part of maintaining the kiln’s moving parts, such as bearings and motors. Proper lubrication reduces friction, which in turn lowers the risk of overheating and wear. However, it's crucial to use the correct type of lubricant as per the kiln manufacturer's specifications to avoid any adverse reactions with the high temperatures commonly experienced in kiln operations.

Here are some lubrication tips:

- Use High-Temperature Lubricants: Ensure the lubricant can withstand the operating temperatures of the kiln.

- Apply Sparingly: Over-lubrication can attract dust and debris, leading to a build-up that could impair functionality.

- Follow Manufacturer Instructions: The frequency and method of lubrication will vary depending on the kiln model and manufacturer guidelines.

Identifying Early Warning Signs of Potential Issues

Developing a keen eye for the early warning signs of kiln malfunction is invaluable. Some of the signs to look out for include:

- Unusual Noises: Rattling, grinding, or screeching noises can indicate loose or worn parts.

- Temperature Fluctuations: Inconsistent temperatures may signify issues with the heating elements or temperature controllers.

- Visible Wear: Cracks, warping, or corrosion on the kiln body or interior could lead to more serious structural problems.

By spotting these signs early, you can take corrective action swiftly and prevent minor issues from escalating into expensive repairs.

Professional Assistance and Resources

There are times when the expertise of a professional is necessary to maintain the health of your kiln. Knowing when to call in the experts is crucial for the safety and longevity of your equipment.

When to Call a Kiln Maintenance Professional

Consider hiring a professional for maintenance in the following scenarios:

- Complex Repairs: If the kiln requires electrical or structural work beyond your skill level.

- Annual Inspections: A yearly professional check-up can give you peace of mind and catch things you might miss.

- Installation of New Parts: To ensure the correct installation and operation of replacement parts.

If you're unsure about any maintenance task, it's always better to consult with a professional rather than risk further damage to your kiln or injury to yourself.

Utilizing Manufacturer Support and Resources

Your kiln's manufacturer is an invaluable resource for maintenance support. Most manufacturers provide a wealth of information and services that can assist you, including:

- Manuals and Guides: Always keep your kiln's manual handy for reference; it contains specific maintenance advice tailored to your model.

- Customer Support: Reach out to the manufacturer’s customer support for advice on maintenance issues you’re unable to resolve on your own.

- Replacement Parts: Purchase genuine replacement parts directly from the manufacturer to ensure compatibility and reliability.

For additional resources and to gain a better understanding of kiln operation, you may want to read through informative blog posts such as Basics of Kiln Drying and Step-by-Step Kiln Drying.

Regular maintenance is crucial for the efficient operation of your kiln. By following these preventive measures and best practices, you can extend the life of your kiln, ensure optimal drying results for products like kiln-dried wood, and avoid the downtime and costs associated with major repairs. Remember, your kiln is a significant investment, and taking good care of it will ensure it pays dividends for years to come.